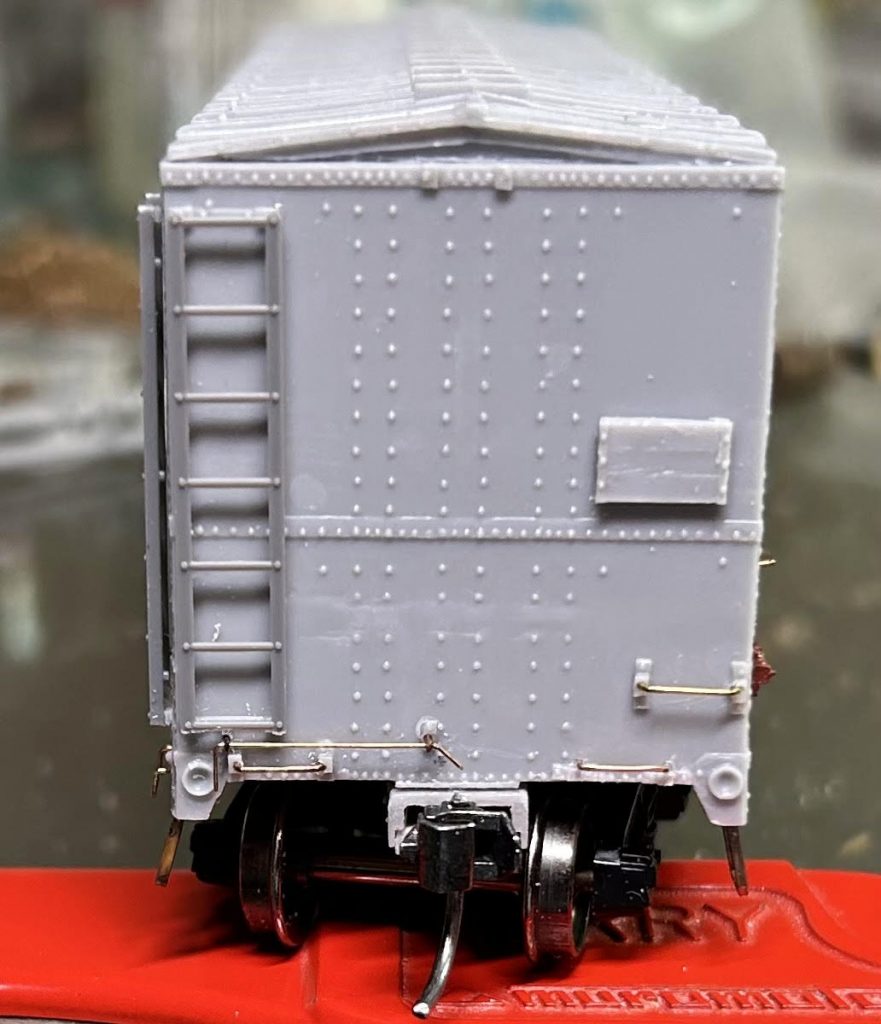

Jerry Hamsmith shares the final chapter of the box car group kit build.

The group building this kit (Ed Rethwisch, Bob Hanmer, Allen DeBraal, Jerry Zeman, and myself) focus on the B end and running board details, and the finishing touches.

Continue reading Central of New Jersey boxcar group build, pt 4