I received this photo and the description below on the day of the previous RCW blog post.

Eric:

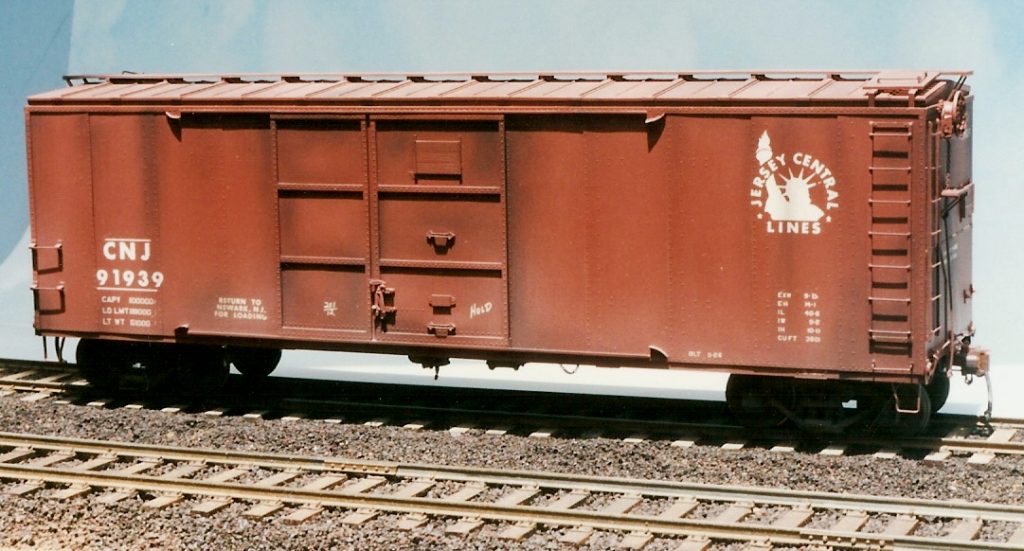

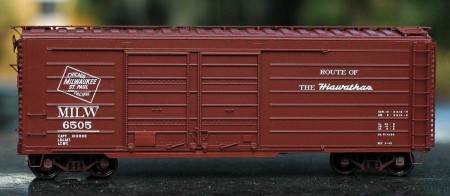

I looked at the RCW blog post and it reminded me of a model that I built in the 1970s. I used styrene as the primary material and impressed all of the rivets using an old converted sewing machine. This was one of my earliest attempts at building a 1/4″ scale freight car using styrene. The model was equipped with trucks converted to 1/4″ AAR (Proto48) standards. The lettering was from an old C-D-S dry transfer set.

Sadly this one picture is the only memory I have of the model.

Gene Deimling

Take another close look at the model and reread Gene’s note and let it soak in. Gene shares more O scale modeling on his blog. Several of his friends also share their fine model work. You should visit and explore his blog. I suspect the O scale modeling there will inspire you to move another project forward. Many thanks to Gene Deimling for sharing his photo and notes!

Happy New Year from the Resin Car Works minions!

Subscribe to the Resin Car Works blog so you don’t miss a new model announcement. Add your email address to the Subscribe function at the bottom of the page.

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. Share the blog link with other model railroaders.