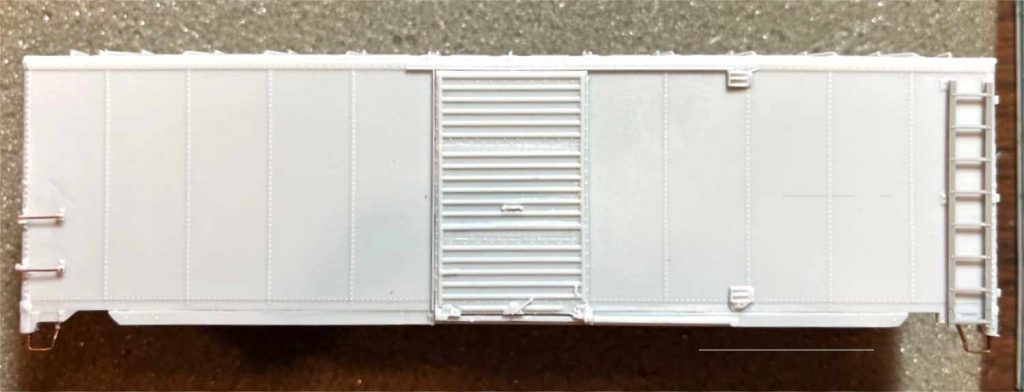

Here’s the fifth and final installment for the Missouri Pacific box car group kit build. Jerry Hamsmith summarizes the steps of getting these models ready to operate on our layouts.

During the 1940s, the typical Missouri Pacific (MP) freight car color was box car red. However, this shade of red had a slightly brown hue.

Continue reading Missouri Pacific boxcar group build, pt 5