Craig Zeni has been working on an HO scale Speedwitch Media kit for an Erie steel-sheathed box car rebuild. Here are his notes.

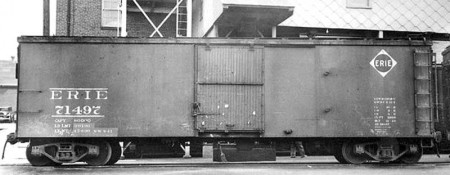

The Erie Railroad embarked on a rebuilding program to convert a series of wood double-sheathed box cars to steel-sheathed cars in the early 1930s. The cars had welded plate steel side sheathing and flexible metal roofs installed. They retained the original doors, earlier braced ends, a vertical shaft handbrake, and an interior height of 8-foot, 6-inches. The rebuilt cars were numbered in the 70000-70999 series with 978 listed in the January 1943 ORER. A set of automobile cars was also converted in a similar manner but with a door width reduced to 6-foot. These were placed into the 71000-71567 series with 565 listed in the 1943 ORER. Speedwitch Media kit K121.1 represents the Erie 70000 series of steel sided rebuilds.

More or less straight out of the box, this kit builds into a very nice model. My changes were minimal. I used Yarmouth Model Works eye bolts, brass strip for the brake step support and running board lateral supports, and a brass brake wheel soldered to the 0.015-inch wire. I made the floor removable, as per my usual practice. I don’t glue in the floor if there’s any way to avoid doing so. As for the brass strip substitutions I felt styrene strip would be too delicate for the former and have never had good luck using styrene strip for the running board lateral supports.

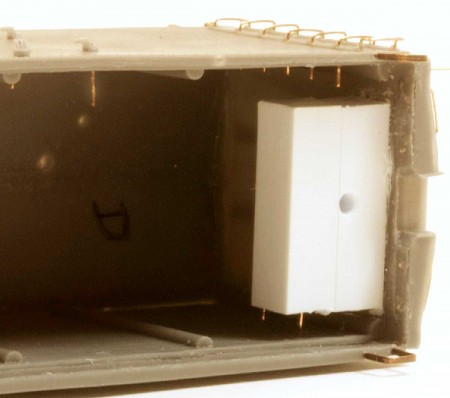

The ladder stand-offs on the ends are resin bits as are the doorstops and door rollers along the bottom of the door. I’m not as speedy as Paul Doggett but this was a pretty quick build for me – about a week of evenings where I dawdle along building. The car is now downstairs on my bench with the silicone sealant curing that holds the weight in place. Paint might be applied in an upcoming weekend.

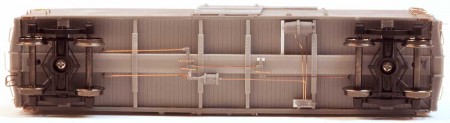

Brake rigging obviously plus a photo showing my styrene floor mounting blocks.

Due to the long end sills on this car and a desire to keep the coupler ‘snuggled up’ against the end sills, the coupler screw is quite a ways back. This necessitated doubling up the 0.25-inch styrene blocks. The bits of wire hanging down in the ‘block’ photo are the grab irons, except for one. I pinned the door stops to the body using Pierre Oliver’s method of drilling thru the part and gluing the wire in place to strengthen the part mount. Hopefully this will keep it from getting raked off.

I would say this kit is a pretty good starter for a resin kit virgin. It’s a one piece body with simple brake rigging, but there are enough small resin fiddly bits to make it a character building experience!

Thank you, Craig, for sharing your work here on the blog. Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, enter your info for a comment and check the last box to notify of new posts by email.

I think your removable floor is an excellent idea. I have done it on passenger and baggage cars but never thought about using the idea on freight cars thanks Craig.

The slow 🙂 Paul Doggett UK