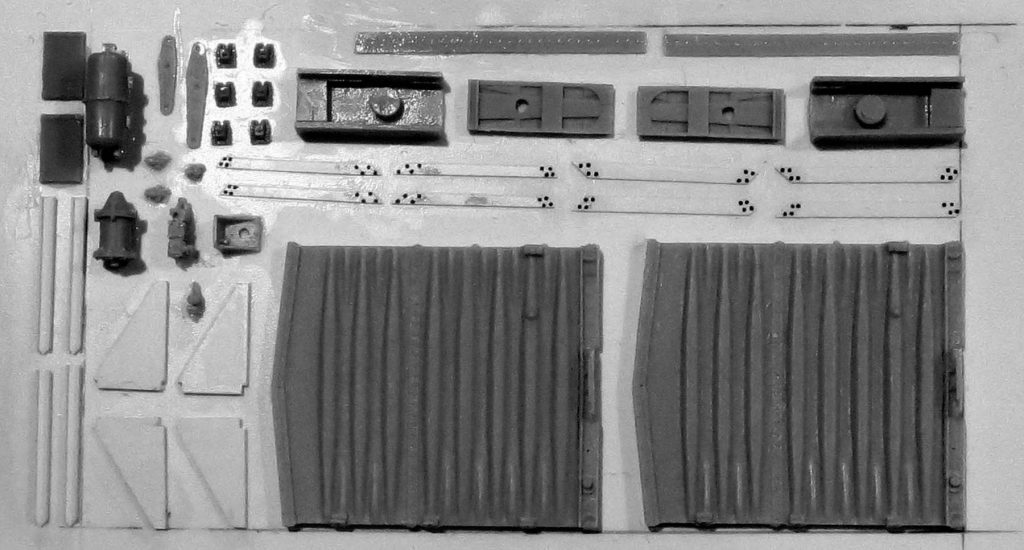

George Toman wrapped up an Illinois Central HO scale boxcar and filed a report. George started with a mini-kit that was given to many RPM Chicagoland registrants. The parts are seen in the lead image. Here’s George with the details.

Each year at the RPM Chicagoland meet the first 100 registrants receive a mini-kit gift. The 2019 mini-kit prototype was an Illinois Central single-sheathed boxcar from the 16000-16975 series. The mini-kit included a set of resin parts and proper decals along with a list of other recommend parts. I always enjoy receiving mine and look forward for ways to improve upon the basic kit and instructions to build a more accurate model.

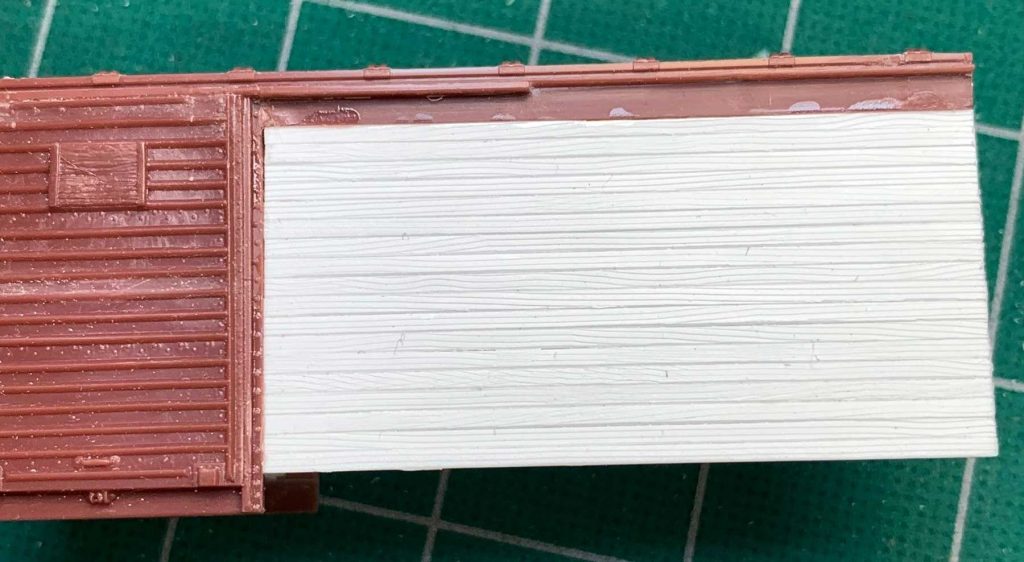

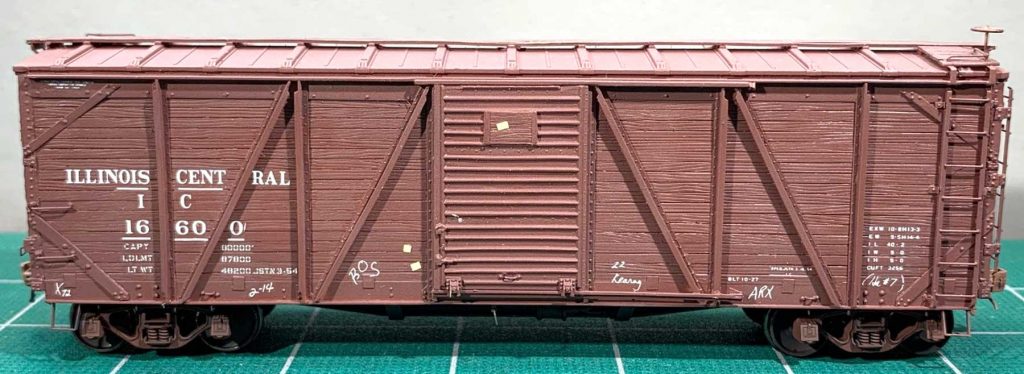

The starting point of this build was an Accurail 7100 series shell with a fishbelly underframe. After studying the photos and the Accurail shell, I noticed the vertical Z-braces were facing the wrong direction. I corrected this by using just the roof and door section of the shell as a starting point. I made new sheathed sides from 0.020 x 0.060-inch Evergreen styrene. The Z-bracing was constructed as a real Z from three Evergreen styrene strips and Archer rivets.

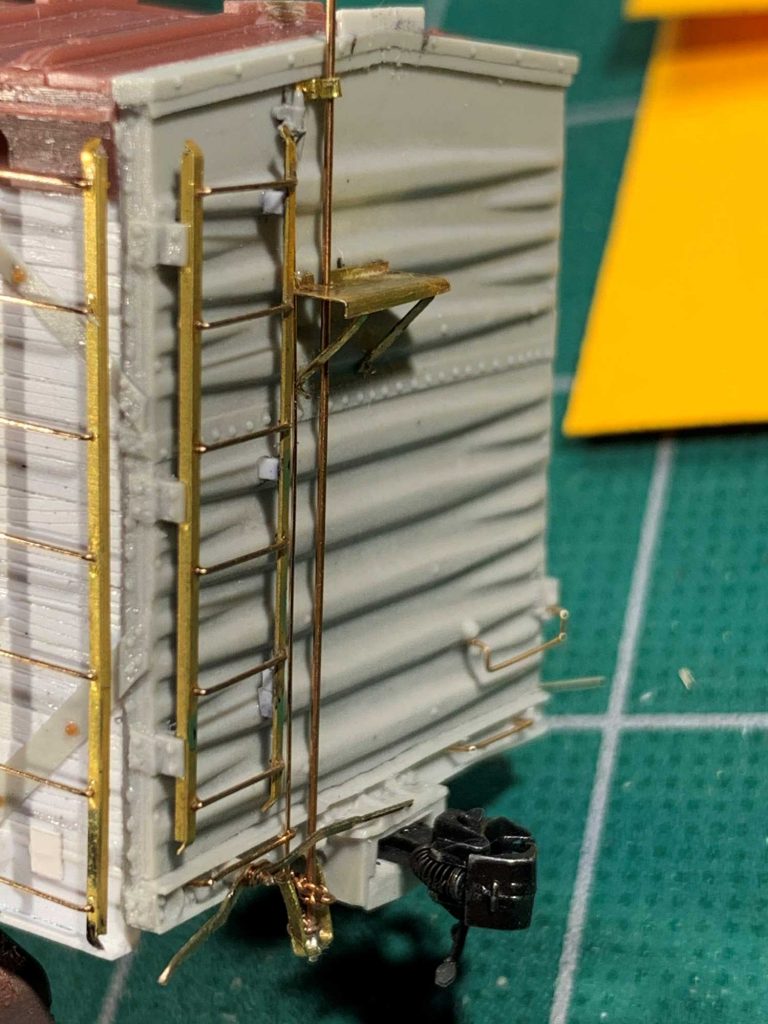

I plan to present a full clinic on building this car at the 2020 RPM Chicagoland. I hope you can be there to attend my clinic. In the meantime, here are a couple construction progress photos.

This was a most enjoyable project! I used new techniques where some worked and others would be approached differently on my next project of this type. I hope you can join me at this year’s 2020 RPM Chicagoland. Stop by my clinic to share my experiences in building this model.

I thank Mike Skibbe for putting together the RPM Chicagoland events, as well as Frank Hodina and his Resin Car Works crew that produce these mini-kits.

Thank you, George, for sharing your fine model building techniques. The new Z-braces look incredible.

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, add your email address to the function at the bottom of the right column on the main page. Share the blog link with other model railroaders.

Really nice work, George. That photo of the detail on the end really showed your high quality work and your attention to detail!

For those of us that won’t make it to the RPM, it begs the question: what were the new techniques that worked and didn’t?

Brian, One item that I would change is not to be as aggressive with the wood grain on the sides as I feel it is a bit more worn than I pictured. I also change some of my materials from styrene to brass for the brackets to attach the ladders to the body and ends. So I discuss a bit about my feelings on the pros and cons of styrene vs brass. Also I use a combination of Archer, Shaved, Tichy and Punched Rivets on this model and show where and how I used them. These will be in my presentation that I make available as a pdf file after its presentation and Mike Skibbe posts on the RPM website.

George

Thanks for the kind comments. The Ladder Stiles are to exact scale that I had Photo Etched for another project but worked out to be what was needed for this car.

Excellent , excellent model. The z-bracing definitely places the model in the extreme modeling category. Craftsmanship at it finest.

Lester Breuer

Impressive work! The etched ladder stiles and exterior “z” posts are nicely executed.

Superb modeling as always, George. Looking forward to additional details in you clinic this year.