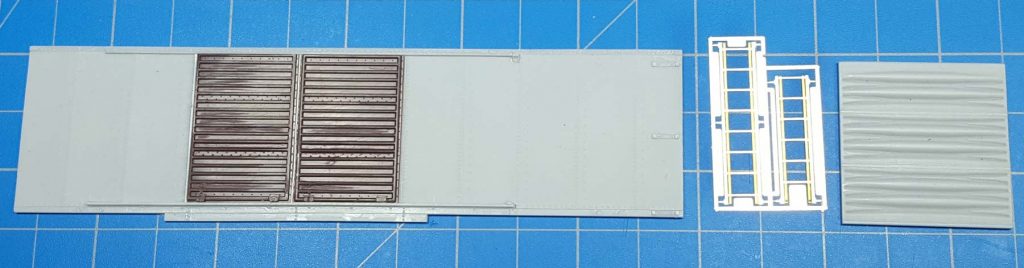

Frank Hodina sent details on new etched metal ladders. Plano Model Products will be introducing these soon with more on the way. A set will be included with the upcoming Resin Car Works Soo automobile boxcar kit.

The images show Plano’s tall etched freight car ladder with an 18-inch width and seven rungs at 18-inch spacing. It makes a fine replacement for some plastic details that are no longer available any more.

Frank installed them on a Sunshine NP double-sheathed car as a test. These are pre-production samples as the finished ones have more connections to create the side angles.

Plano has also done ladders for early steel cars, like the NKP automobile boxcar. The end ladders have the correct 16-inch width.

A bending tool such as those available from The Small Shop is a requirement to form these photo etched ladders. Don’t even try to bend them with pliers as it can’t be done.

If you’re crazy enough you could use Archer rivets to detail the rungs.

Frank

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, add your email address to the function at the bottom of the right column on the main page. Share the blog link with other model railroaders.

Note the “required” bending tool is $50, making this a bigger investment than the kit you want to use this for. If you have a small business that builds resin for profit, the investment makes sense, but if you only want this for a few cars, it seems to be an expensive tool.

Oh! I see their smallest “Mini hold and fold” tool is $30, but I don’t know if that is big enough to do a ladder. (Depends on the height of the car.)

I think the LOOK of an etched ladder is fantastic, and I’d love to try some, but it’s a substantial investment for the tool (the price of the ladders themselves, from other sources, is not bad).

Dean, the cost of tools is amortized over time with each use. Etched ladders are a detail that has come of age. I suspect the cost of a bending tool will quickly come down to an investment of $2 per kit for some modelers. The same could be said for a motor tool or an airbrush. – Eric

These are very interesting, but, I do not like etched metal parts. When Pacific Mountain Scale Shops produced their B&O cabooses, they offered an upgrade kit with etched metal. The rungs were flat, no 3D look. When Pocahontas Models issued their boxcar kits, they used etched metal for the brake pieces. Again, very flat looking that lessened a unique and well-done car.

I like the Scale Shops tool. Bought it several years ago and find it handy not only for etched parts but also for bending up sill steps

Seems to preclude the use of the poling pocket, doesn’t it? (Does anybody still use poling pockets?) (On 1940’s cars?)

Usually I like to support effort that give us improved parts but I do not like the look of these. The flat rungs ruin it for me. If the rungs were finer maybe but other than being metal, I do not see these as an improvement.

Mr Welch,

I think the point is that the plastic parts manufacturers are going away, and that you soon will not have other options. just my take.

LJC

Maryville,IL

A question…

I was wondering if an etching can be made of/for, the Sacramento Northern RR’s Square Number boards that were used on SN’s GE 44Ton Diesel Locomotive’s and Tidewater Southern’s GE 44 toners and GE 70 ton locomotives? Just a thought.

A drawing of the number boards can be found in “Sacramento Northern On Line” originally developed History and Research by Mr. Garth G. Groff.

In regards;

Richard Young.

My first exposure to this type of an etched ladder was in the ‘war emergency’ reefer kits from Sunshine. There are pros and cons to both the open stile edge and the closed stile edge represented by Yarmouth Model Works. The open edge (Plano) has the advantage of being a one piece etching with rungs attached to the stiles, but the disadvantage that the opening at the stile bend is visible, even after painting. Sunshine instructions suggested filling the gap with thick CA before painting, but I found that approach less than satisfying. The YMW etched ladders have separate stiles that must be bent, then the rungs are attached to form the ladder using a jig constructed by the modeler. The pros are that the stile is one piece with no edge gap, but the con is that the stiles are more difficult to bend and adding the rungs can be tedious, even frustrating. For overall appearance, I prefer closed stile by YMW.

Why not a two stage etching to include the rivets for those of us not crazy enough to use the Archer rivets for that purpose?

It looks like it’s already a two-stage etching, to get the rungs to stand proud of the stiles…

Hello…

Just read your announcement for the new ladders and doors. They look great and I hope you have lots of success with your new product.

Sincerely;

Richard Young.