Frank Hodina, Resin Car Works chief minion, has been tinkering with a shelf queen this summer. Here’s his report.

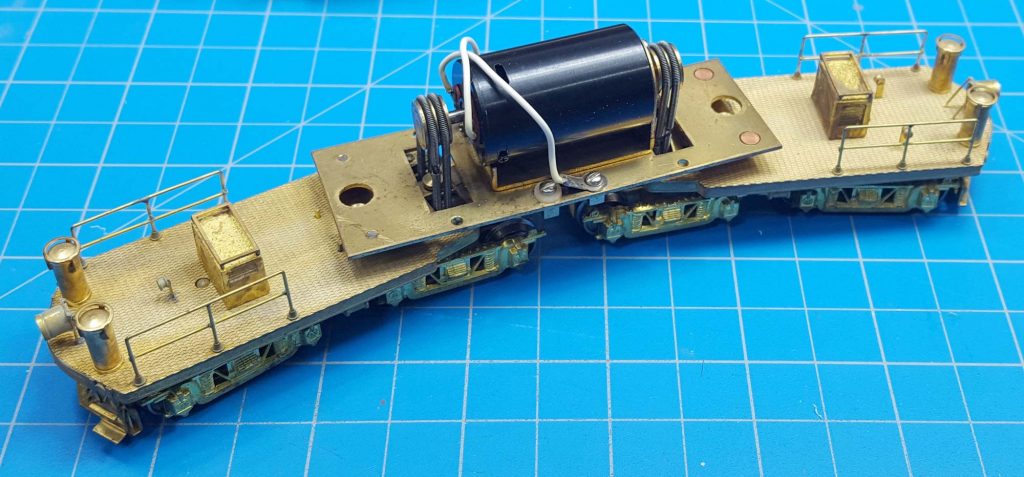

I have several pieces of Illinois Terminal equipment that have been sitting for years. I got the itch to play around with a Class D motor to see what I need to upgrade.

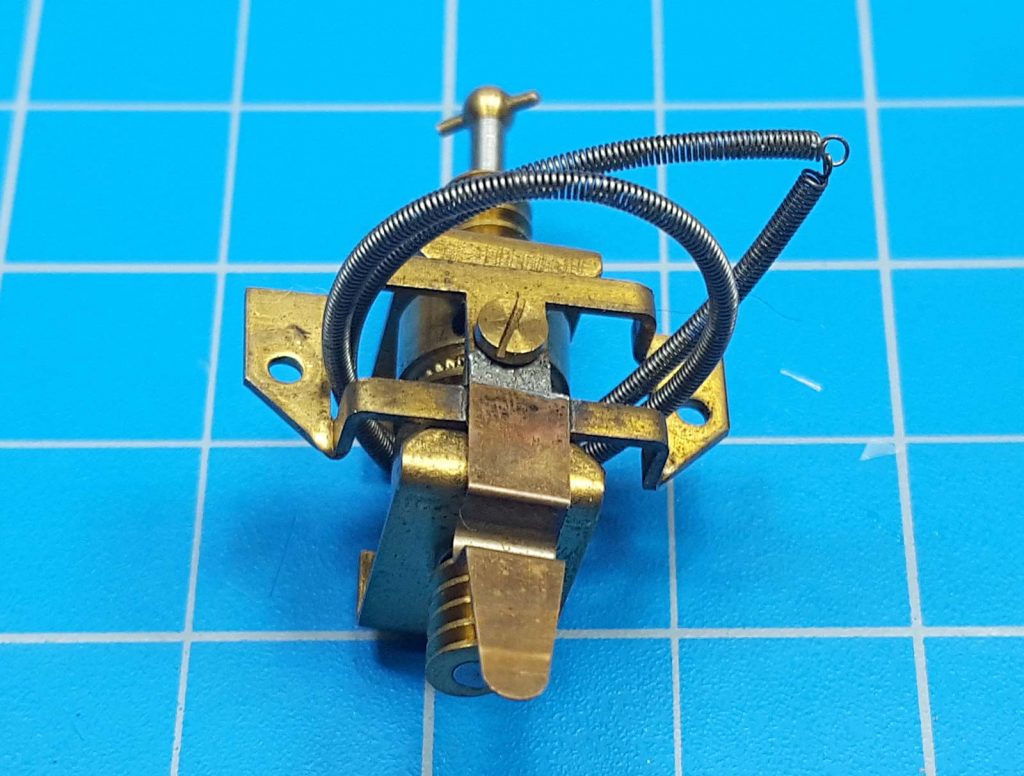

I couldn’t figure out how to install decoders as the metal spring drive made it impossible to isolate the motor from the frame. A discussion about old Athearn rubber band drives on the RepowerAndRegear discussion list on Groups io sparked an idea.

I ordered some of the drive belts from ScaleRailroader, which cost $5 including postage. I put RCW work aside and spent an evening tinkering, something I haven’t done for a long time.

First problem was how to install the belts as the truck bolster frame is one piece.

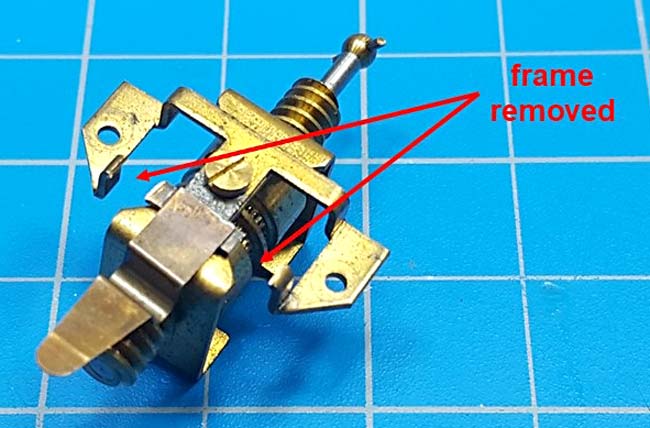

I took a radical approach and cut sections of the bolster frame out. The brass is heavy enough that there doesn’t seem to be any harm done.

Then I reassembled the drive to test.

The unit ran well with a lot less noise, but there were still a couple issues. I found that one truck lifted some off the rail and that the motor wasn’t parallel to the frame. So the drive was taken apart again. The motor mounting bracket was filed until the motor sat correctly. The brackets that attached the articulated units to the body floor were each insulated with 0.005” styrene and nylon 2-56 screws. Both drives need to be insulated so that the body and motor are completely isolated. I finished up the Class D drive by adding a piece of 0.040-inch thick styrene between the body floor and those two center bars to level out the trucks.

I can’t believe how well it runs.

The unit was taken apart (again) for paint prep. We’ll follow up with a post on painting and decoder installation. My goal is to have the Class D painted and running for RPM Chicagoland. Then it’s on to modifying and painting several other pieces of Illinois Terminal equipment.

Maybe I’ll have a spot on the layout like this shot of IT 74 at the Rents stop, southwest of Dawson, Illinois on the line between Springfield and Decatur.

As you can guess, Frank Hodina is always busy with something interesting on his workbench. I’m looking forward to seeing his Illinois Terminal motor on display at RPM Chicagoland.

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, add your email address to the function at the bottom of the right column on the main page. Share the blog link with other model railroaders.

Isolating the motor from the frame only app;lies to older open frame motor (OGM) where one of the commutators (poles) is connected to the motors frame. This can be corrected with a simple piece of heat proof material fitted in exactly the same way as the other pole.

In this case a can motor is being used and there is nomrally no connection between the poles and the case/ armature of the motor.

Class C or D? Top photo is of a Class C(note the

blower boxes and cylindrical sand boxed while

the rest show a Class D pilot.

Does the fix work for both?

Mark Godwin

Yes, works for both Suydam Class C and Custom Brass D.

Top photo from my collection, Sandy Goodrick photo. I wasn’t quite old enough to shoot these electrics.

Thank you, Mike. The photo credit has been updated. – Eric

– I have several (Suydam) Class C locomotives running on DCC with metal spring belt drive. Same with several other interurbans with this setup. Apparently it doesnt hurt the decoder to have contact between motor shaft and engine frame.

Really interesting reading and a great job. I am interested in how you install the decoder in this unit.

Thanks for Sharing,

Jim Ford

I love this! My favorite part of the hobby is playing Dr Frankenstein. Thanks for sharing.

Frank,

Please let me know the next step. I am looking to do the same with a Sudyam

Trolley so as to add a decoder.

Joel