Bill Welch has adapted the HO scale Kadee brake gear and brake wheel detail parts to use in updating other models. Here’s Bill with his techniques.

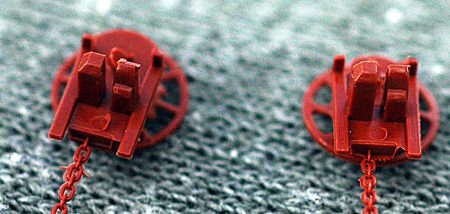

I have known for awhile now that Kadee sells their assembled brake gear and wheel part direct to consumers. A phone call was recently placed to Sam Clark at Kadee and I ordered a variety of their parts even though I was not sure how I would attach them to models. I know Detail Associates offers brake wheel and gears but they are getting hard to find and they are not a finely rendered as the Kadee parts.

The backside of the Kadee gear has four projections that serve to attach them to Kadee ends. Two of these are fairly large and square making it hard, at least with my little brain, to figure how to mount these on an end unless I created a hole in the model end. Hmm, what to do? Then it came to me:

Cut off the mounting pins and sand the back of the casting flat

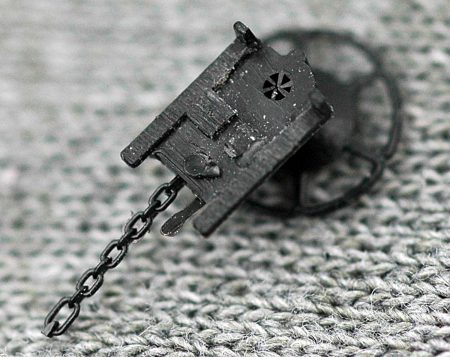

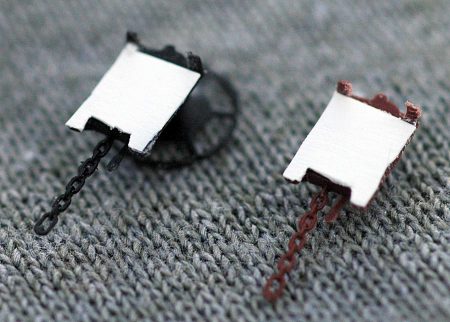

Laminate 0.005-inch thick styrene to the back using Loctite Plastics Bonding System. Trim the thin styrene to taste and glue the assembly in place with Testers or Tamiya styrene cement, if applying to a plastic model.

In the case of the Georgia USRA steel rebuild box car in the photo, I left the two small projections at the top rear of the gear to aid in the placement on the model—they are butt against the top rib to help keep the assembly level. I will decide on a case-by-case basis whether to keep them or not. I have created a drill template if I decide to perhaps drill into an end as a part of locating and attaching the Kadee part. I forgot the trim the bit of white styrene behind the chain but the entire end will eventually be painted black so not a big deal.

By using close-cut nippers I was able to trim the rod under the chain very closely. The bottom link of the chain is large enough to fit 0.012-inch wire through. I used chain-nose pliers to form a small loop in the wire and small pliers to close the loop around the chain link.

Here’s a direct link to the parts Kadee has available.

We thank Bill Welch for sharing a simple technique to adapt the Kadee brake components to other models.

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, enter your info for a comment and check the last box to notify of new posts by email. Share the blog link with other model railroaders.

To answer questions in the comment section, RCW hopes to offer a number of housings and brake wheels on one parts sheet direct from Shapeways. This post illustrates what was received as a test print. This is a work-in-progress. Things can change and other issues may delay this introduction but we will post an update on the blog when these become available. – Eric H.

Nice work as always Bill

Your link takes me to a list of Kadee’s detail parts such as coal loads, running boards, doors, ladders – and brake *wheels* . They have several types of brake *wheels*, but I don’t see the gear boxes shown in your illustrations. Does Kadee have a second page of special details?

I see the link to the brake WHEELS but not to the brake GEAR?

Yes, that’s my question too: which brake *gear* types are available, and how to buy them?

Beautiful! Looks like something even I could do.

Maybe in his phone call to Sam Clark Bill was able to get parts that are not listed in the link to Kadee that Bill posted. Great work as is usual for Bill.

I can’t tell you how much I appreciate your RESIN CAR WORKS website. I have spent hours going over many of the prior postings and always find many interesting tips.

I’ve been phoning in direct orders to Kadee for the entire brake housing, staff, and fulcrum assemblies since 2010. They are available for Ajax, Universal, Miner, Universal, Champion, and Equipco housings and wheels. I retain the brake staff instead of cutting it just under the chain. I remove the mounting pins from the staff, and cut it to length for the car I’m building so that it will fit into the Kadee fulcrum and clevis, which I drill with a #80 bit to accept the staff. This way the entire Kadee assembly is used without the oversized wire and mounting loop and Tichy turnbuckle clevis. I glue the brake housing directly to the car end without the styrene backing plate. Bill, I finally found a case where I’m more extreme than you are ; )

Some nice tips on attaching these finely rendered parts. I just got some Equipco & Miner versions for a project so this is a very timely post. Thanks for sharing your techniques