Pete Hall has been busy working on HO scale steam locomotive models. He sent photos and details on how he adds a speaker and extra weight to the boiler. Here’s Pete with more.

This began with a task to install sound in a CB&Q Mikado. The tender cavity is small because of the deep coal bunker, so the electronics fills that space and precludes installing my standard 27mm speaker. I decided to install a 691-1291 Bowser twin-sugar-cube speaker in the boiler.

The 691-1291 is an excellent speaker with remarkable range and volume. Putting it into the boiler has the advantage of putting the sound where it was generated, up forward. Of course, installing the speaker in the boiler conflicts with installing the cast cylindrical weight that comes with the model. I started searching for places to by other shapes of lead weight.

Frank Hodina suggested where to buy sheet lead, McMaster-Carr. I bought a sheet of 1/16 inch, cut a piece 2 x 3 inches, wrapped it around a dowel, and inserted it into the boiler. The cast cylindrical weight weighed about two and a half ounces. The sheet lead replacement weighed a bit more, nearly three ounces. I gained both weight and room inside the boiler. I can add more lead sheet if needed as there is a little room left on either side of the gearbox, or even inside the firebox.

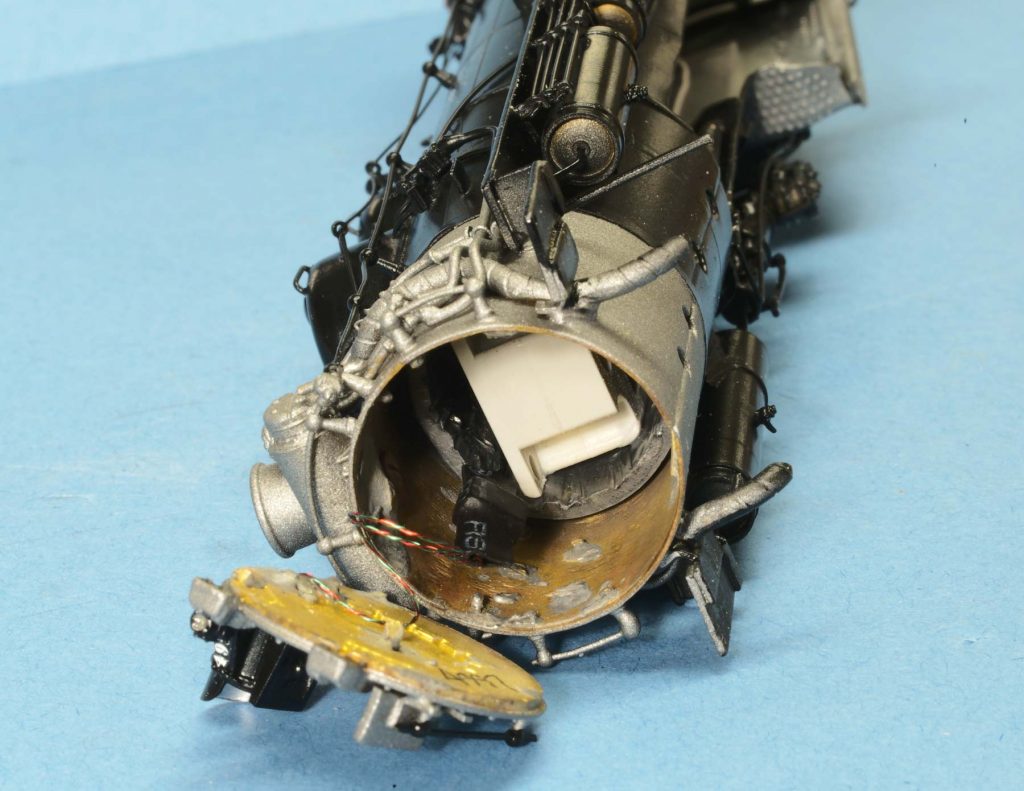

I used various pliers to expand the sheet lead inside the boiler until it fit snugly, leaving room for the gearbox to fit into the cavity. I sanded the square edges of the speaker enclosure until they were rounded. The speaker was inserted into the boiler from the smokebox end and held in place with Canopy Glue.

In this image, you can see the dull gray lead sheet, the end of the white speaker enclosure, and its red and yellow wires that are held in place by gray mounting tape. The other electronic device is the current limiter for the headlight LED. This solution works remarkably well.

Many thanks to Pete Hall for sharing more steam locomotive upgrade ideas. Who would have thought the sheet lead would weigh more than the cast part that came with the loco?

Questions and comments can be posted below. Please follow the instructions so your comment can be posted. All comments are reviewed and approved before they appear. To subscribe to this blog, add your email address to the function at the bottom of the right column on the main page. Share the blog link with other model railroaders.

Where does the sound exit? Through the gear tower opening below, or the stack? Some brass models have open stacks, which would seem to be the perfect place for sound to escape.

Actually, the sound exits through the bottom opening of the engine. Plenty of airspace there. Unfortunately, the stack is secured to the smokebox by a screw, so no way to open that as a sound vent.

Another great trick I’ve seen is using a round speaker and creating the speaker enclosure from sheet lead to replace the weight.

A good idea, and one I used in the past before sugar-cube speakers were available. However, I compared the 3/4″ round speaker to the sugar-cube, and the SC blew the round speaker out of the room.

Quote – The other electronic device is the current limiter for the headlight LED. Is this a standard resistor or something more?

The LED comes with the current limiter attached. The LED is the Pico size from Evan Designs.

Years ago we carved a notch in a piece of wood dowel (to clear the gearbox) and made a 2 piece plaster mold we used to cast lead weights using scrap wheel weights. We cut to appropriate length and turned them on a Unimat if too big diameter.

Did the same thing – have cast a lot of boiler weights myself. If I were doing a larger engine, I’d have to evaluate the possibility of adding more weight by using a casting in addition to the wrap for the sugar-cube.

A key point that needs to be re-iterated is that the weight on a steam locomotive needs to be done so that it is balanced on the center of the drivers.

Yes, I always balance the engine in the middle of the drivers. This wrap technique actually puts about 1/3 more weight directly over the gearbox so it is in a good location for balance.

From my years of designing HO scale models of steam locomotives for others and importing them under the New England Rail Service names there are a couple of comments I’ll make that might be heipful here. Firstly, I believe Pete’s method of adding additional weight is far better than the all to often seen method of simply filling all empty boiler room with Cerrobend melted and aloowed to simply flow into the boiler shell. To me that is a major loser. That is because of the importance of having the reassembled model balance at the mid-point of the wheelbase of the drivers. That is the only point at which a model should be balanced, NOT the mid-point of the entire wheel base. I have seen models with the boile filled with Cerrobend and then had the life run our of them. A Toby made, Toby being one of the best Japanese builders, model of a Canadian Pacific G-3 class 4-6-2 was received some years ago that was stated to be in “excellent” condition by some dunce in Barnaby, BC.

This model felt like a lead brick it had been so filled with Cerrobend. Unfortunately it was of no value with no available spare parts as there was little, if any, plating left on the drivers and the gearbox was completely worn out. In conclusion I would say that adding a bit more weight to many brass steam models is perfectly reasonable but use some common sense and don’t go overboard. If you are gogin to add weight, or even improve the manufacturers weighting the most important thing is to be as careful as you can to have the final effort balance the model as close as possible over the center point of the driver wheelbase. That is how our NERS model of a small Boston & Maine K-7 class 2-8-0 was rated by the late Bob Higgins, the most scientific and careful reviewer of the running qaulities of brass models we have ever had, as able to pull 120 cars (See the May 1986 issue of the NMRA Bulletin) on straight and level track after testing a model with no special preparation received from someone who had purchased the model from a dealer in the western US.